DIY Hobby Spray Booth

5 comments

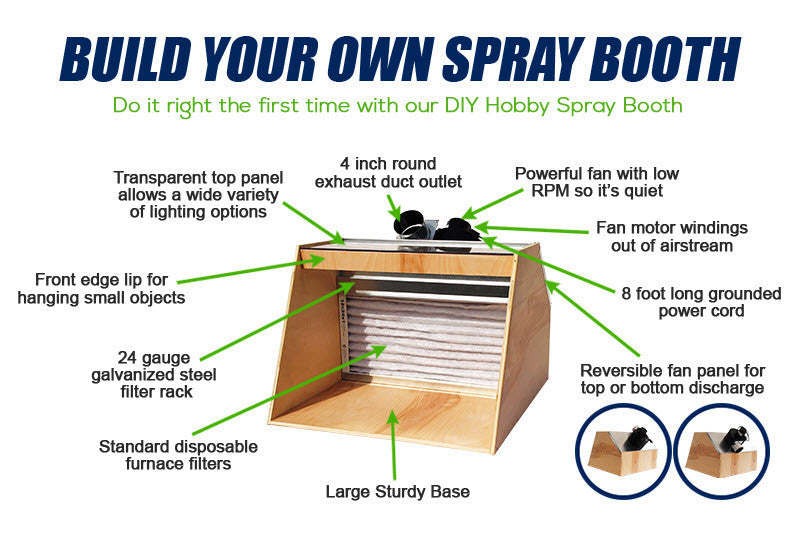

Build Your Own Spray Booth

Build Your Own Spray Booth

We recently created our own hobby spray booth, it worked out very well for us so we created this article to show you how we did it. Choose the type of wood you prefer, follow the instructions, and start building your spray booth now.

Hobby Spray Booth Specifications

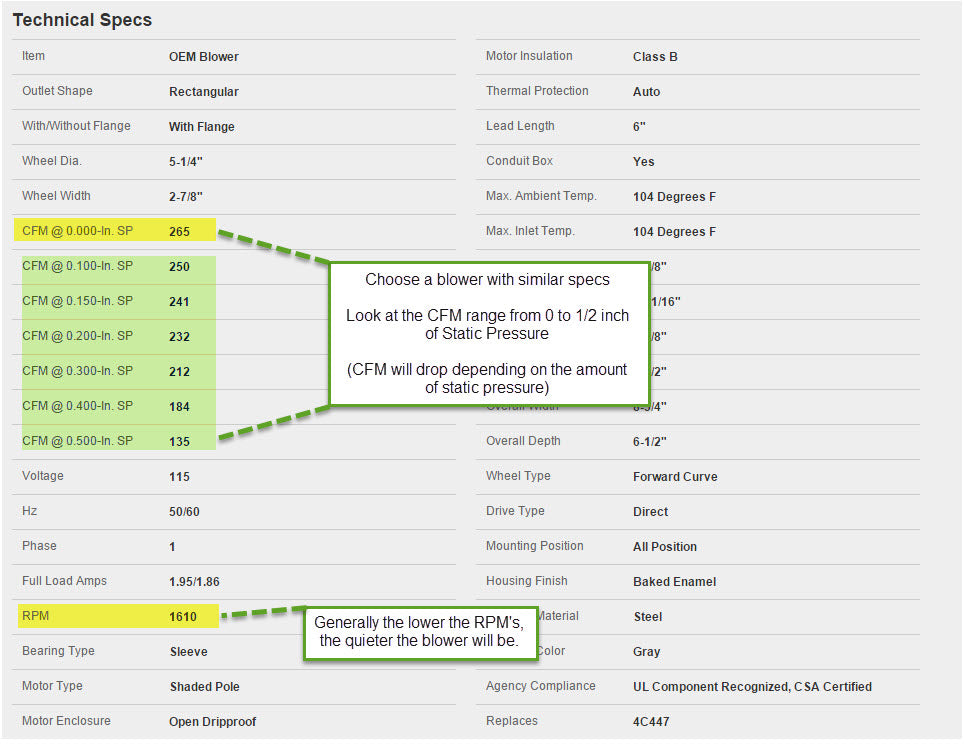

- 265 CFM exhaust blower, 115 volt, 1.9 amp, 1500 RPM.

- 7 foot long grounded power cord.

- 24 gauge galvanized steel mounting panel for blower.

- 24 gauge galvanized steel filter rack, for use with standard furnace replacement filter. 12" x 24" x 1"

- 4 inch round exhaust duct outlet for easy venting (standard dryer vent)

- 1/2 inch thick plywood for bottom, sides, back and front panels.

- 1/4 inch thick plexiglass for top panel.

Choosing A Blower For The Hobby Spray Booth

We know that Grainger's retail pricing can be pretty expensive so we suggest you shop around, if cost is a concern. If you choose to use a different blower and your exhaust duct run is longer than 8 feet, make sure that it will hold up to static pressure similarly to the Dayton blower.

Make sure the important specs are similar to the image below.

Cording The Blower

These types of blowers do not come corded so you will have to get a grounded power cord and cord it yourself. This process is extremely simple, it's literally just 3 wires; 1 positive, 1 negative and 1 ground. Don't worry you won't need any prior experience or knowledge of electricity to cord the blower.

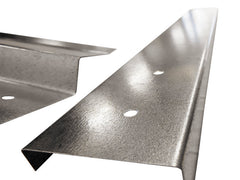

Fan Mount Panel

We used 24 gauge galvanized steel for the fan mount panel so that we could have top or bottom discharge just by flipping the panel. We externally mounted the blower so the motor windings would not be damaged by harmful paint and solvents.

Learn more about the Fan Mount Panel

Square To Round Fan Adapter

When we built our spray booth we created our own square to round adapter. People started asking us where to get an adapter, so we started looking for an adapter that would work. After much research we came to the conclusion that there were no adapters commercially available that would properly transition from the square flange of the blower to a round duct outlet. This is when we realized that we could add value if we made this adapter commercially available.

This product enables the Dayton Blower 6FHX9 to be vented using standard 4" inch diameter circular duct. This adapter can be used with rigid, semi-rigid or flex duct.

Note: You must bend the flange flush with the blower housing for the adapter's bolt pattern to lineup properly.

Warning: It may not fit other blowers because flange sizes and bolt patterns vary.

Learn more about the Square to Round Fan Adapter

Filter Rack

When we created the filter rack for our spray booth we used 24 gauge galvanized steel, we are aware that it won't be possible for most people to use this material. The filter rack can be made out of wood it could be the same plywood you use to build the booth. See below if you want to buy a Vent Works steel filter rack.

Learn more about the Filter Rack

Lighting

We decided not to include internal lights in the booth itself, instead we used Plexiglas as the top panel. This way light would easily shine down into the booth and we would be able to quickly adjust the light depending on where we are and what we are doing. We recommend 1/8" to 1/4" Plexiglas, but you can use any translucent material. Local hardware stores should have something usable in stock but thickness, size, and materials may vary. We used a table saw to cut the material but a circular saw will work. Make sure to set the saw blade depth so it just clears the material or the material may split, crack, or chip.

Wood Alternative

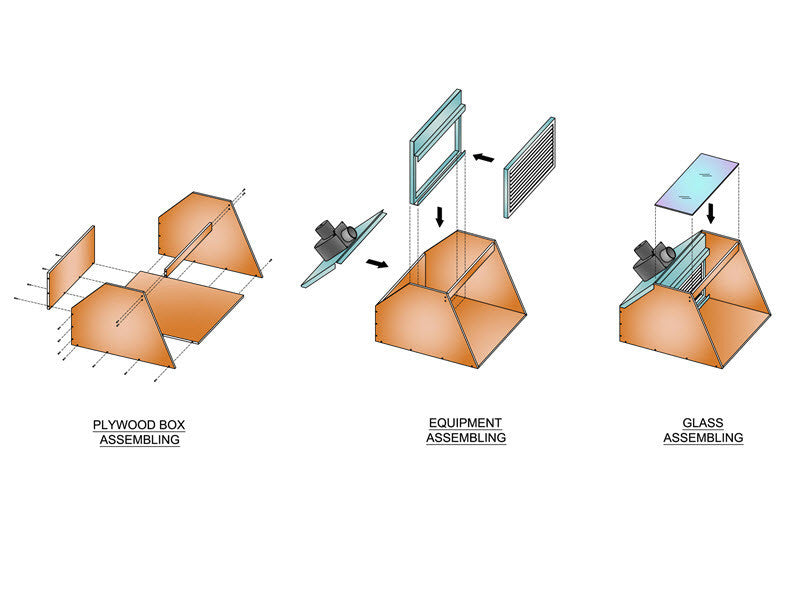

The spray booth used in this article was constructed using a Vent Works Filter Rack and Fan Mount Panel, but if you prefer you can make those parts yourself using wood. If you do use wood for the fan mount panel you will have to create the panel, cut the hole, drill pilot holes in the panel and in the blower, get proper hardware and weather seal.

Below are images of a booth built using the same plywood for the booth, filter frame, fan mount panel, and the top panel (instead of the Plexiglas).

FAQ's

- ▼

Is this spray booth explosion proof?

-

.No, to be classified as explosion proof, a vapor proof motor and switches must be used. Explosion proof components are very expensive and would make this booth cost prohibitive. However, for an explosion to occur, the concentration of flammable vapor must be at or above its lower explosive limit (LEL). In most cases, if the fan is running before vapor is introduced, the concentration of vapor will be diluted and less than its LEL. - ◄

Will the spray booth require maintenance?

-

Yes, periodically filters should be replaced and ducts should be inspected for obstructions. This will ensure proper air flow which will reduce the risk of vapor buildup. - ◄

How far can I run the exhaust duct?

-

Exhaust ducting adds friction (resistance to airflow) therefore you should locate the booth as close as possible to the exhaust termination. Vent Works recommends no more than 15 feet of exhaust duct when possible. - ◄

Where can I buy exhaust vent pipe?

-

.The hobby spray booth that we created has a 4 inch round exhaust outlet that can be vented with standard dryer vent ducting, which is readily available at most hardware and home improvement stores. - ◄

Will the exhaust air from the spray booth damage vegetation near the exhaust outlet?

-

No, if the booths filter is in place and properly maintained, over-spray and particles will be removed with no damage to plant life.

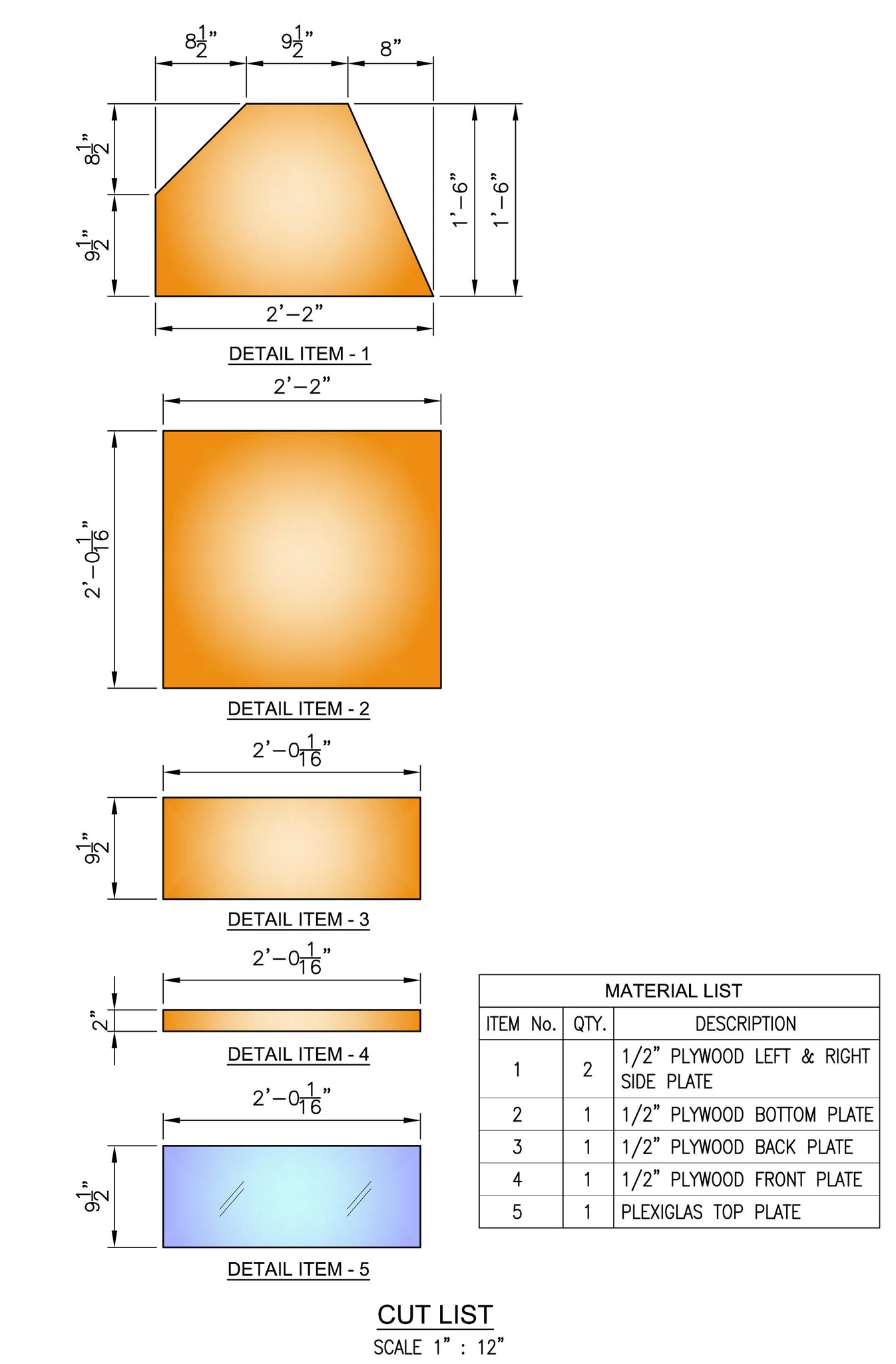

Cut List & Assembly

Download Cutlist & Assembly Instructions Below

DIY Hobby Spray Booth Assembly Instructions & Material Cut List

If you enjoyed this article please pass it along, share it with friends and others that would find it valuable. The buttons below make it extremely easy so please take a moment to share, it means a lot to us.

Thanks

Vent Works

Build Your Own Spray Booth

Build Your Own Spray Booth

Comments (5)

Just bought the square fan adapter and filter rack from ventworks. Now just have to locate the Dayton 6FHX9 and get it. A trip to Lowes or Home Depot for the 1/2 inch plywood and a few other parts and I should be fine. Maybe even see what cheap paint returns they have and put a nice paint job on her with some pinstripes maybe a flaming skull or two.

Looks like a real nice spray box thanks for the plans Vent Works Alex B.

Great article I cant wait to start my build. Thanks!

I was in the same situation as Dustin (second posted comment) in that I was looking for a good quality spray booth for my hobby but couldn’t see spending $400.00 plus dollars and I didn’t want the cheaper plastic one(s) being offered either: I came across ventworks youtube channel and found exactly what I was looking for in a hobby spray booth … good quality product and simple plans to make it happen. I ordered all the parts shown here on the website as well as the window vent that ventworks produces … once I received the items I purchased a piece of 1.25" white plastic sheet from Home Depot and a small piece of plexi glass and built my spray booth. It works AWESOME … quality products and making out of white plastic allows the inside area to be bright and easy to clean off afterward … these are great products and I hope ventworks is able to continue producing the items. I plan on passing along the website to the scale modeling communities I belong to on YouTube and Facebook because there are a lot of builders I think would be interested in purchasing these materials and building a high quality paint booth of their own!

Thank you for sharing this info…it’s just what I’ve been looking for. I’ll let you know how it all works out after I get it built and use it for a while. Can’t imagine it won’t work very well….

I have been searching for an affordable hobby paint booth for some time. I just couldn’t justify spending $400+. I found the Vent Works DIY kit that included the plans, sheet metal and blower, but unfortunately due to high demand of their other products they had do discontinue this offering. As a testament to true customer support Vent Works went out of their way to include this blog on the website so that others like myself can build an affordable paint booth with detailed instruction all the way to a link to the exact blower that came on the DIY kits. I actually emailed Vent Works a couple of times with questions prior to the addition of this blog and Kyle has always been quick to respond with detailed answers. Vent Works is a company that will no doubt continue to grow and thrive, even amidst a weak economy, due to outstanding customer service. In a time when it is difficult, sometimes impossible, to speak to or get a reply from a real person, Vent Works graciously reaches out to its customers to address questions on a personal level. 5 stars!

Dustin Rhodes

North Carolina